Today Open Bionics announced the release of their first open source 3D printed robotic hand kit. The ‘Ada hand’.

The team, based in the UK’s Bristol Robotics Lab, have released their first robotic hand called ‘Ada’ complete with tutorials, detailed build instructions, and bill of materials. Check it out on their website or on Instructables, Thingiverse, and Youmagine.

The project is currently featured by editors on Instructables.

Open Bionics said they wanted to offer the robotics, maker, and 3D printing community the easiest to make open source robotic hand, and this release can be built within an hour.

Instead of spending tens of thousands on robotic hands for research robots like Baxter, Open Bionics says build your own for £500.

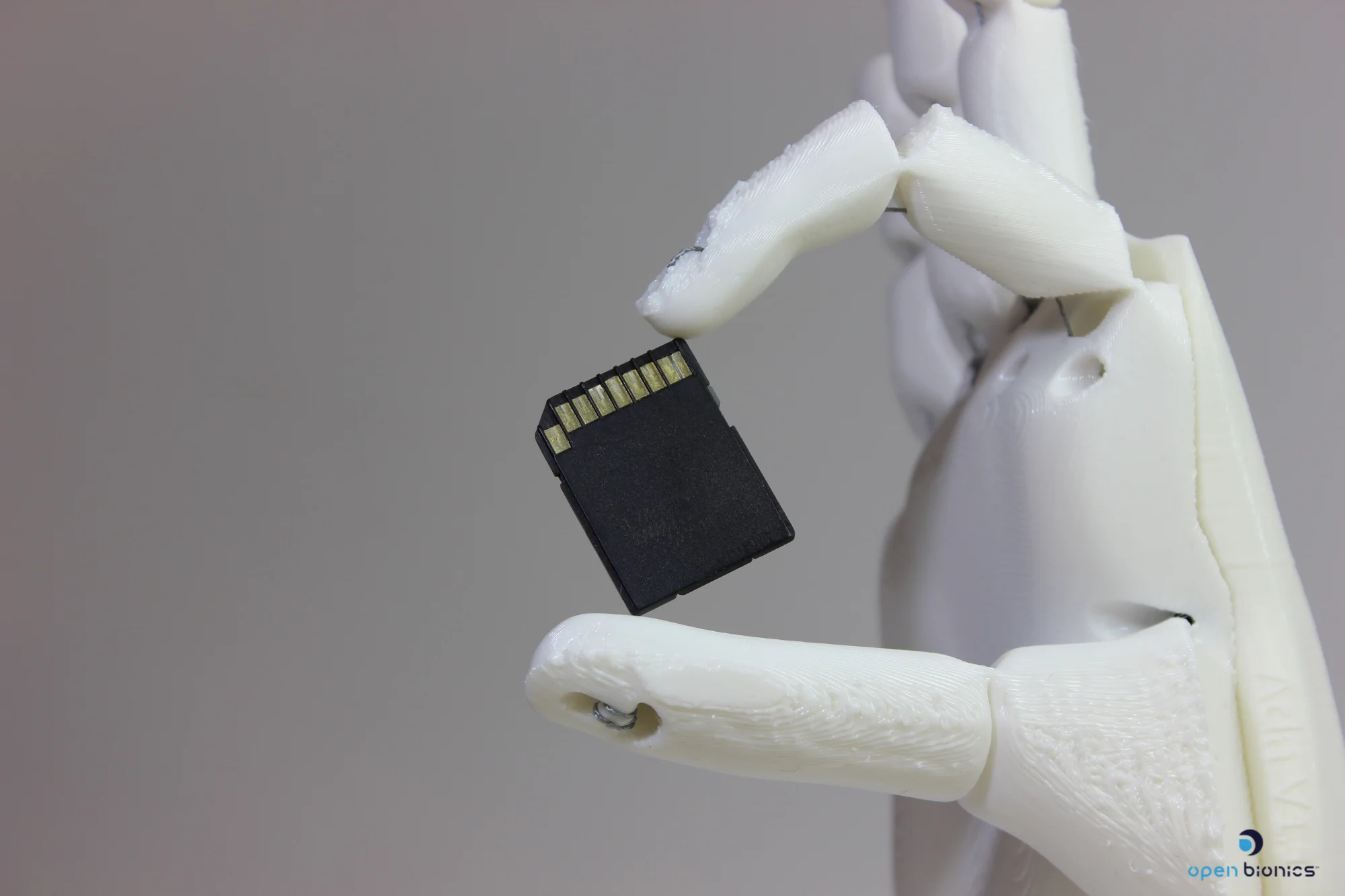

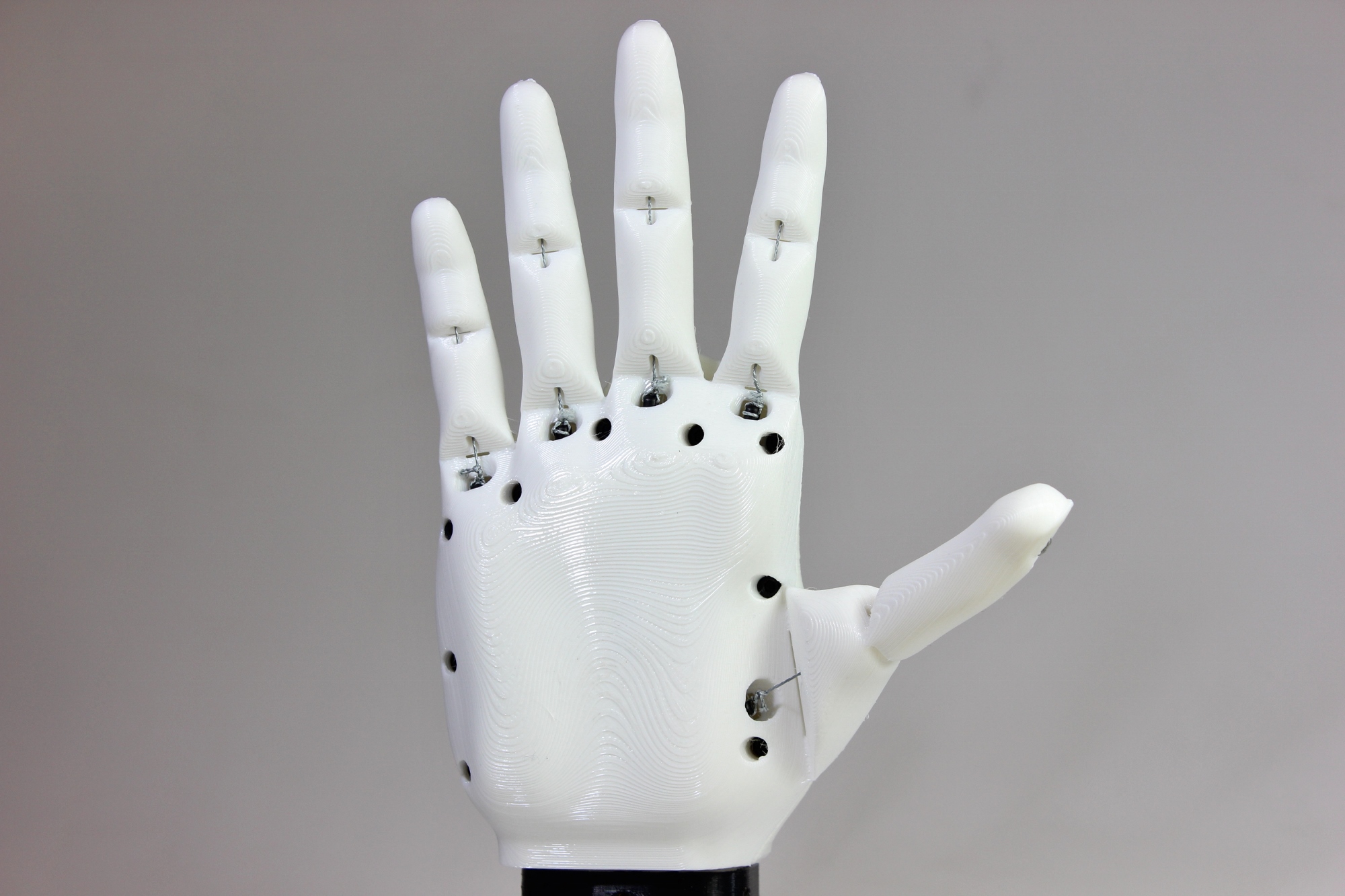

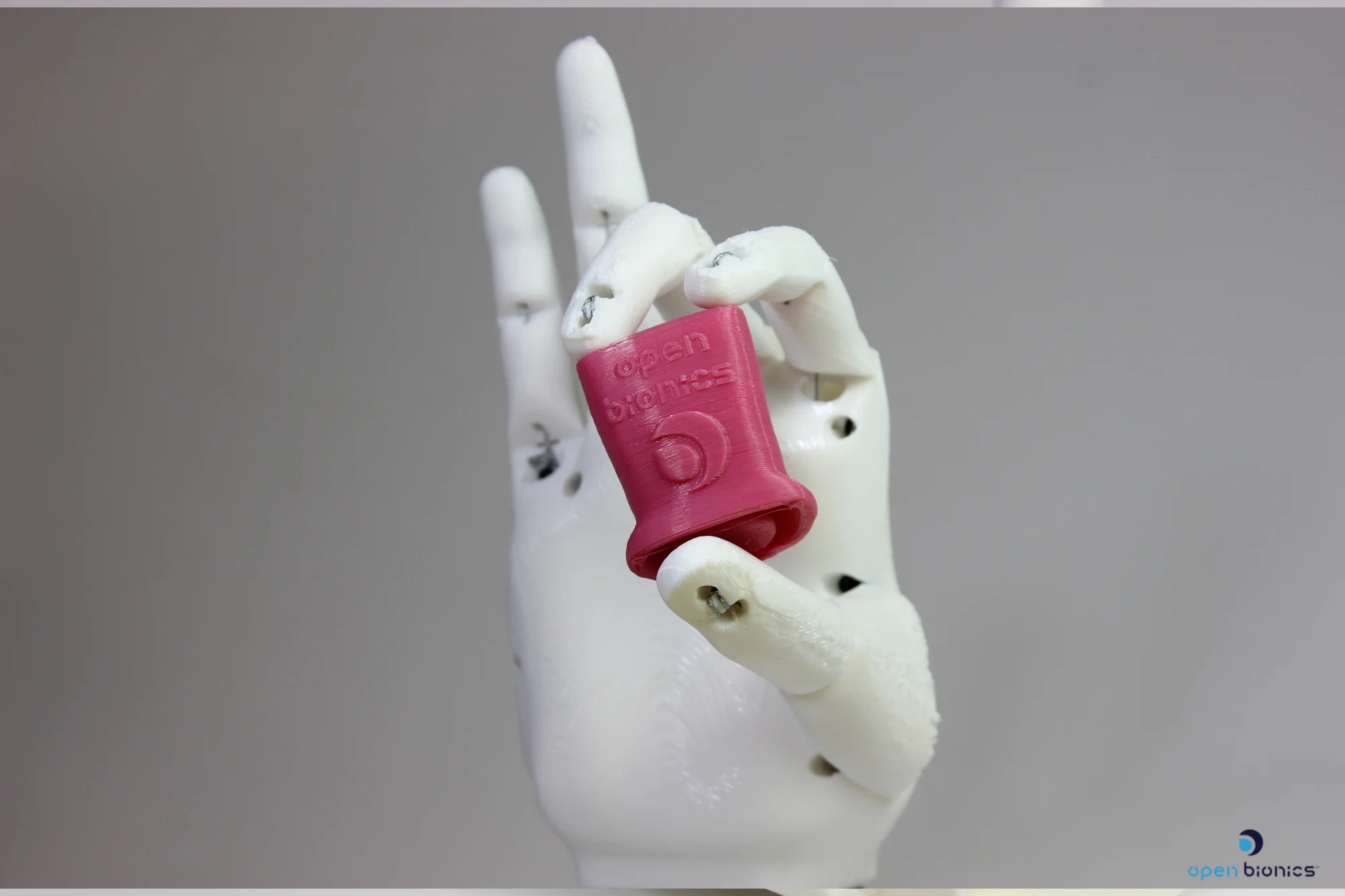

The Ada Hand is a fully articulated robotic hand from Open Bionics. It is a kit of parts and can be assembled in around 1 hour using standard tools. The hand has 5 degrees of freedom (DOF) and can be controlled from a PC or MAC over USB connection. The Ada hand houses all of the actuators required to move the fingers as well as its own custom control printed circuit board (PCB). The PCB is based around the ATMEGA2560 microcontroller and can be programmed using the Arduino programming environment which will be familiar to many developers.

The Ada hand is perfect for anyone that is doing a project with robotic hands or wants a neat, light, and functional robotic hand for use with a humanoid robot.

Open Bionics’ ‘Ada’ hand is very different to the original ‘Dextrus’ hand. The print and assembly time has been made radically faster and easier.

Joel Gibbard, Open Bionics’ CEO, said the team wanted to make robot hand building easy.

“We know there are hundreds of people around the world that really want to contribute to designing a fantastic robotic hand, both for applications in robotics and in prosthetics. At the moment there is a large barrier to entry to getting involved in this project and contributing to developments. With the Ada hand we want to remove that barrier. The hand is 3D printable on an FDM desktop home printer and can be assembled in an hour, we’ve also created a developer community so people can sign up and post their developments in our forums. We’ll constantly be suggesting bite-sized projects for developers to take on and taking feedback from them about what else they need."

“I think one of the big barriers to people making and starting projects is a daunting magnitude of the build and a lack of documentation, instruction, and guidance. We are trying really hard to make sure we have detailed and easy to follow assembly instructions, comprehensive data sheets, and lots of tutorials to suit all levels of ability.

“We’re trying to make this as easy as we can for people with any level of technical ability. For example, if a researcher is studying robot interaction and needs a robot hand, but building a robot hand from scratch isn’t part of her/his project and they’re looking at affordable options, we want this build available to them and for it to be quick and easy.”

Part of this move is to encourage developers to post their research in the newly opened Open Bionics’ developer forum.

Joel added: “We receive a lot of emails from researchers who want to buy or make our hands. But we receive more emails from researchers and makers who want to contribute to our goal of making low-cost 3D printed bionic hands readily available for amputees. We’ve had a handful of researchers who have used our hands to contribute to award-winning medical research and prosthetic testing. We’re hoping that by making our robotic hands easier to make, we’re opening up the possibility for more researchers to get involved and contribute.”

Open Bionics named their robotic hand after Ada Lovelace, celebrating Lovelace’s contribution to programming.

Olly McBride, Open Bionics’ Software Engineer said: “Ada's vision was to develop the capability of computers to go beyond mere calculating and number crunching, our robotic hands are an embodiment of this development as embedded programming has enabled us to programme multiple grip modes for this hand.”

This was a big release for Open Bionics. In the week since the developer forum opened they’ve had 109 makers, engineers, and amputees sign up to contribute to our research and development.

Open Bionics is an award-winning robotics company creating affordable 3D printed bionic hands for amputees. Last year they announced a deal with Disney to create official Iron Man, Star Wars, and Frozen hands for amputees.

Join the Open Bionics developer community! 3D print your own hand with a print time of 24 hours or buy an assembly kit with all components here.