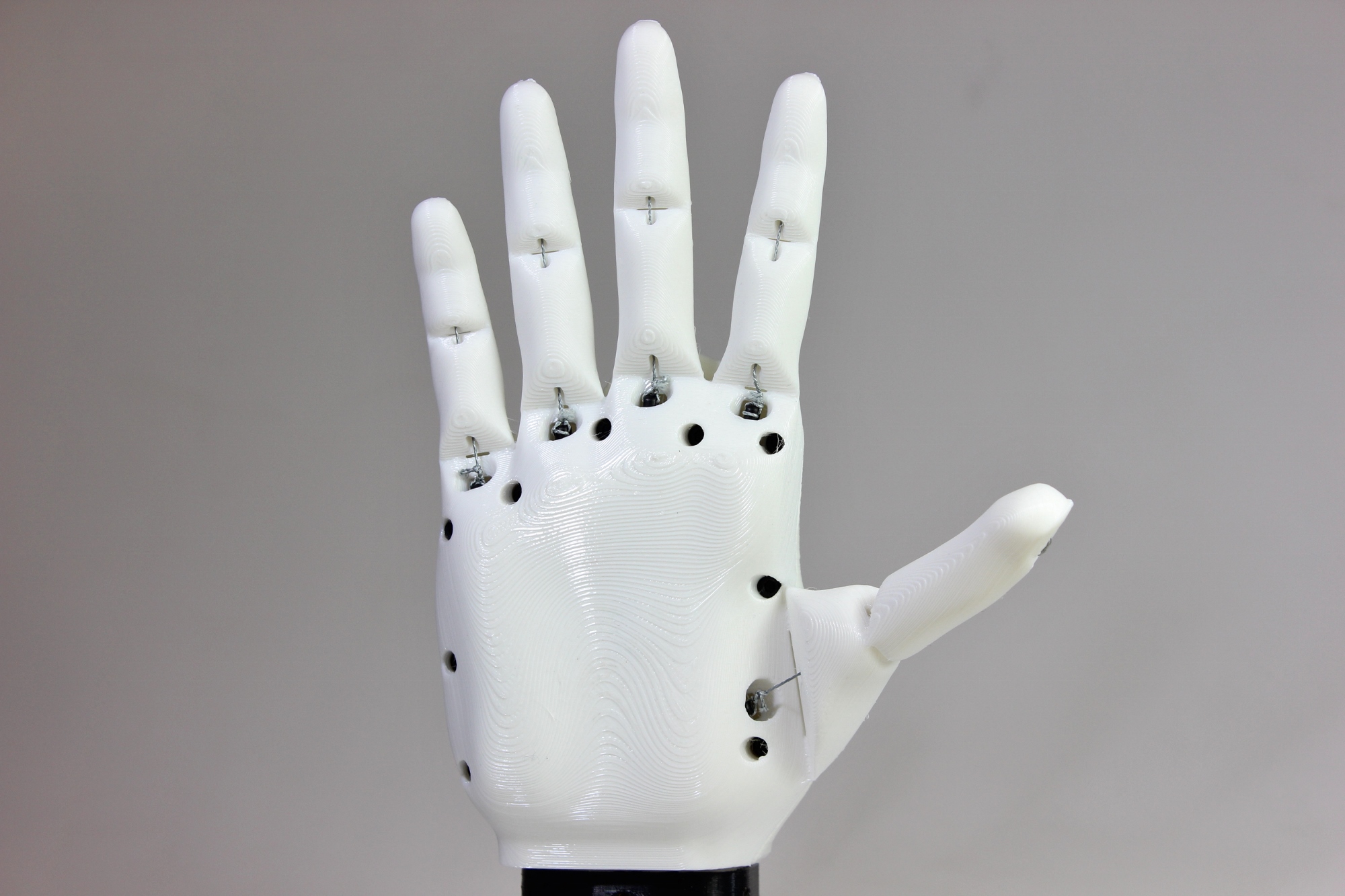

Last week we ran our first batch of object testing with our latest 3D printed prosthetic hand design. We’ve been experimenting to find out which grip modes will benefit amputees most.

In the video below you will see objects being handled that are different weights, heights, sizes, and shapes. We also had a mix of rigid and flexible objects, and objects with handles and without. We chose to test 25 objects selected from amputee feedback and academic research. Most of the objects were pointed out as being a ‘must be able to handle’ by amputees, if this bionic hand is to be useful for everyday use. We found this research on ‘Role Analysis of Dominant and Non-dominant Hand in Daily Life’ very helpful.

The bionic hand in this video is capable of handling 5 kilos of weight and demonstrates this by picking up the loaded shopping bag.

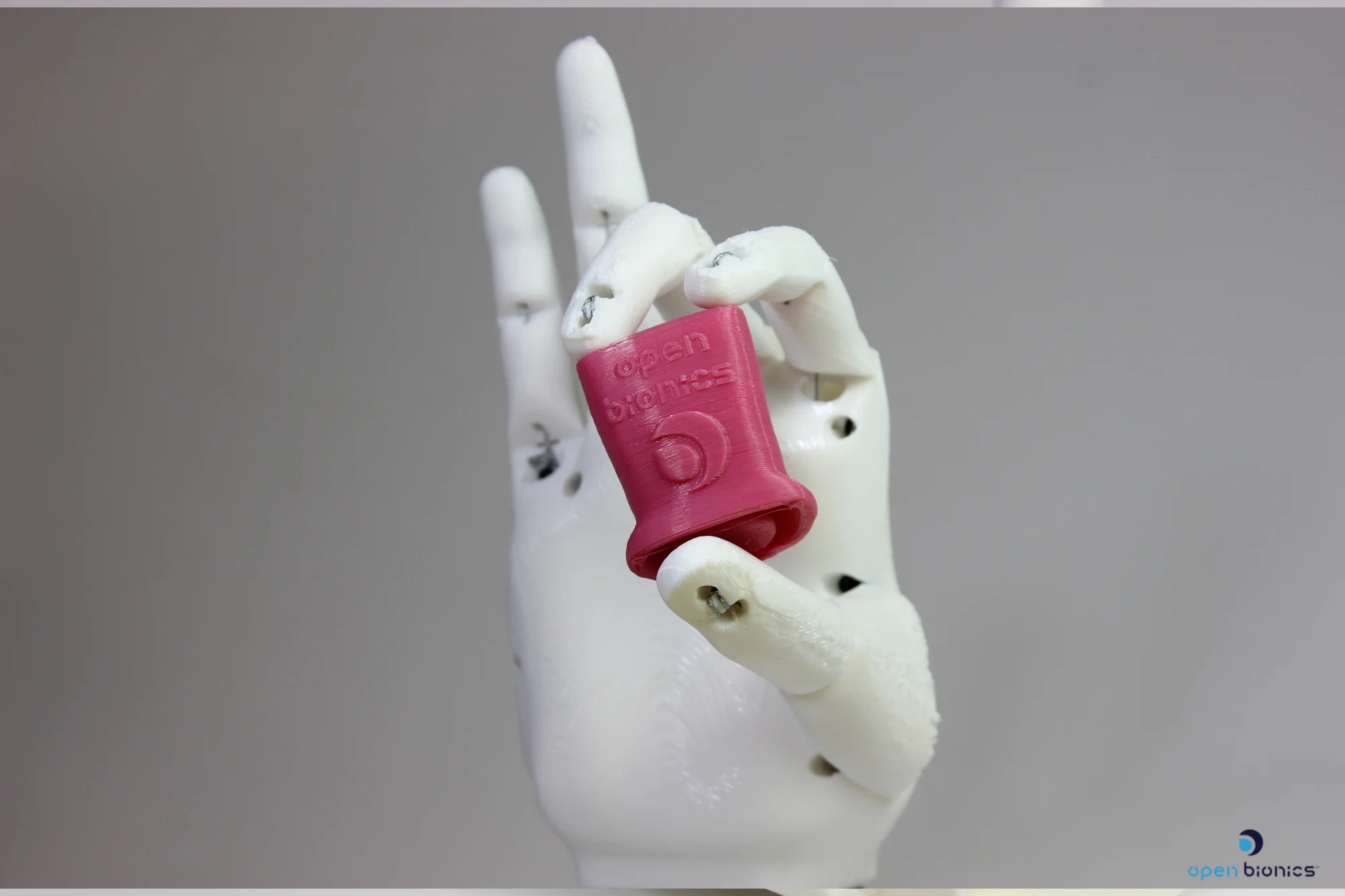

This test was designed to see how our bionic hand can manipulate objects. You’ll notice this test wasn’t performed by an amputee. We created a 3D printed handle to test the hand because we didn't want to inconvenience an amputee volunteer for every test run. We'll share this handle design with you soon. We have since tested with an amputee and we’ll share that video with you next week (check out the sneak peek below of Dan picking up a marble).

This 3D printed bionic hand can be controlled via EMG sensors to perform multiple grip changes. In this video we are testing the following grip modes:

Full open / close

Hook

Thumbs up / down

Index finger point

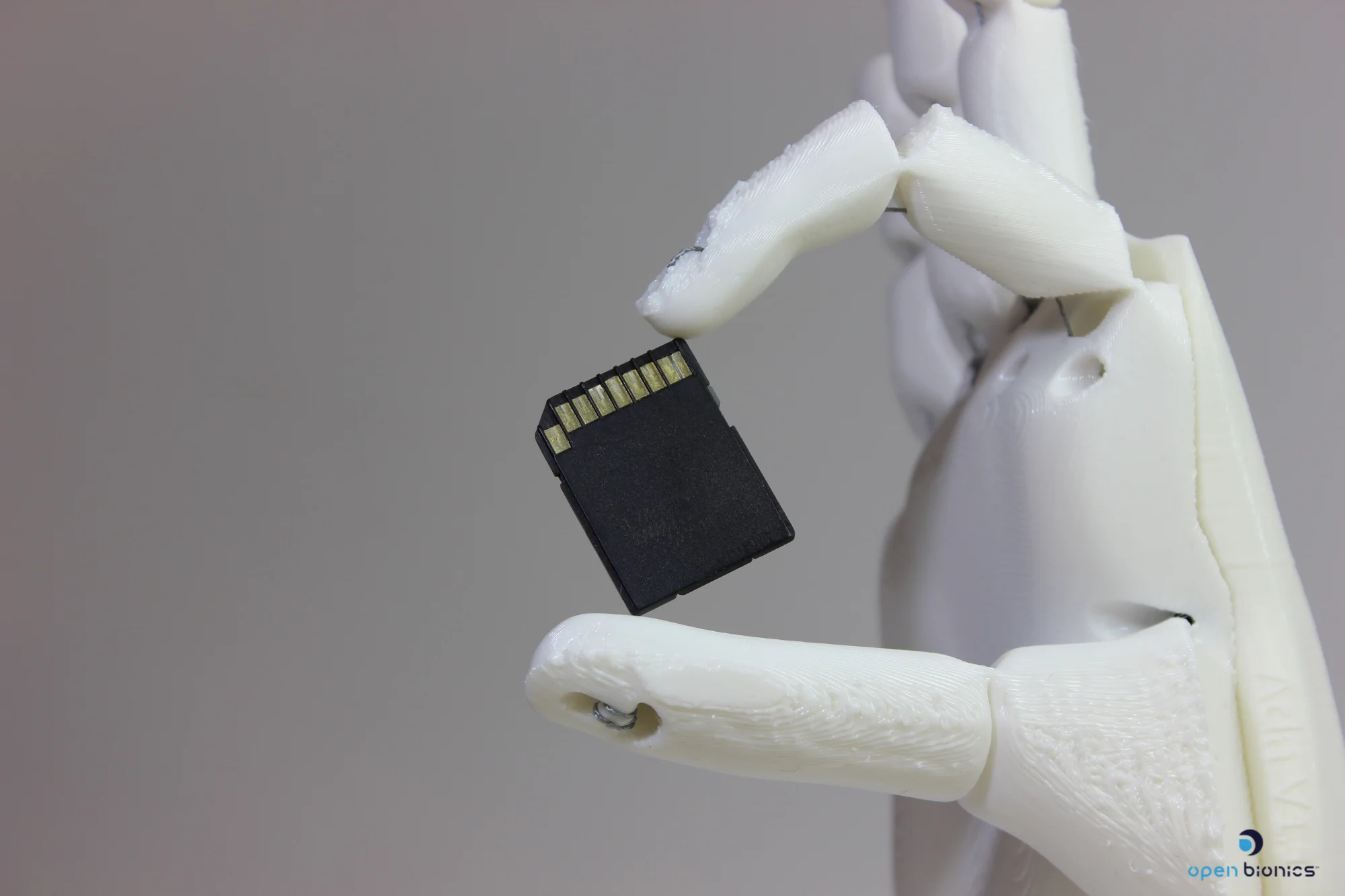

Pinch grip

Tripod grip

This prosthetic also has proportional control. This means amputees can choose how much power to move their fingers with, this affects the speed and force of grip. So, an amputee can hold a bottle and choose to squeeze the bottle harder if they think the bottle might slip.

Although a lot of the testing was about handling objects, some of the grip modes are there to make gesturing easier. For example, the ‘index finger point’ has been highlighted to us as really important by amputees who use a split-hook or cosmetic prosthesis. Sometimes it can be a struggle to accurately point things out when you don’t have a working index finger.

We've been using micro gel finger tip grips to give the fingers more friction. If you know a better solution please share your idea with us on our forum.

All of the grip modes demonstrated in this prosthetic hand can be found in our robotic 'Ada hand' for researchers and makers. The 'Ada hand' isn't built to be a prosthetic but a research platform. We are still developing our prosthetic hands.

Next week we’ll show you how this bionic hand can be used by an amputee to manipulate various objects and perform everyday tasks. We’d be really interested to know if there are certain tasks you’d like to perform easier, or certain objects you’d like to be able to grip better. Let us know by tweeting us or writing in the comments on Facebook!